Tube Ice Machines |

|

|

|

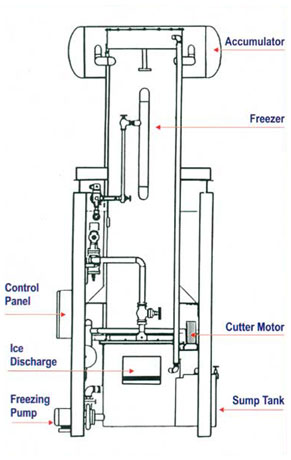

The Unique design of our Tube Ice Machine Freezes Ice automatically in the Vertical Stainless Steel tubes by the Refrigerant circulating around tubes in freezer shell.

The Swril of water falls from the top of each tube, the hole is formed during the formation of Ice because of the falling film of water, freezing takes place inside the vertical tubes, as the water freezes the impurities are washed back to the sump tank to be released as and when required, when the Ice in the tubes is frozen to the desired thickness.

Hot gas is released automatically in to the freezer Shell releasing tubes of lce on to a cutter, the cutter cuts ice pieces of desired preset length. |

|

| |

|

The cylindrical Ice is available in three standard diameters 1 3/8", 1 1 / 8" & 7 / 8", Standard length is approximately 1" or can be designed to

customers requirement. |

| |

| |

Our staff strives to ensure that the Tube Ice Machines are among the strongest,

withstand years of rigorous use. We are constantly working to improve

efficiency, ruggedness, reliability of our tube Ice machines to keep us ahead of

competition. |

| |

Our Tube Ice Machines are designed to satisfy the varying needs of different

industries and customers. Our Tube Ice machine capacity varies from 1300 kg

to 40,000 kgs. of Tube Ice per day, our self contained models are 1300 kg. to

5000 kg. of Tube Ice per day and are operational on Ammonia & R-22

refrigerant. |

| |

We supply a perfect Ice machine no matter what's your need, if any of our many

models does not suite your need we will gladly work with you to custom design a

model that fulfill your requirements. |

| |

| ADVANTAGES OF TUBE ICE PLANT OVER FLAKE ICE & BLOCK ICE PLANT |

| TUBE ICE |

| » Highly efficient consumes less power. |

| » Lesser space required

for production. |

| » Ice Produced in batches of 20-25 minutes. |

| » Minimum Maintenance and does not

require any replacement parts for a long

period. |

| » Investment lower than

Block Ice Plant. |

| » Easy delivery through

screw conveyers. |

| » Can be sold in any

packed quantity for

any use. |

|

|

| |

| FLAKE ICE |

| » Very high power

consumption per ton of

Flake Ice produced. |

| » Space required is also

more compared to tube

Ice Machine. |

» It produces Flake Ice

continuously and after

few hours lumps of Ice

are formed and becomes

difficult

for transportation. |

| » Wear and tear is very

high compared to Tube

Ice machine because of

constant movement of

scrapper. |

| » Investment is also

higher and it also does

not fulfill the rated

production capacity. |

| » Requires manual

handling as lumps are

formed. |

| » Cannot be sold In

packed condition. |

|

| |

| BLOCK ICE |

| » High power consumption when not

working in full

capacity. |

| » Very large area

required for brine tank |

| » First Ice Block is

produced in 2-3 days

time. |

| » It requires frequent

replacement of Ice

cans, Brine Solution,

Spares for Hoist,

Agitator etc. |

| » Very high investment

in building, land &

plant equipments. |

| » Ice blocks being very

heavy requires manual

harvesting & Handling. |

| » Can be sold only in

blocks. |

|

| |

| All Purpose Tube Ice Machines Best For: |

| • Sea Food Processors |

• Hotel |

• Bars |

• Restaurants |

| • Fishing Industry |

• Concrete / Cement Mixing Plants |

• Air Lines |

• Flight Kitchens |

| • Meat Processing Plants |

• Poultry Packers |

• Dairy Plants |

• Bakeries |

| • Chemical Industry |

• Catering Services |

|

|

|

| |

| |